Within many environments, ID badges are regularly put to the test and need to be replaced frequently. With limited budgets and resources, how can you better manage your ID issuance program and get the most out of your access control and security investment? Let’s provide you with five different ways for you to help extend the life of your ID badges!

1. Composite ID cards

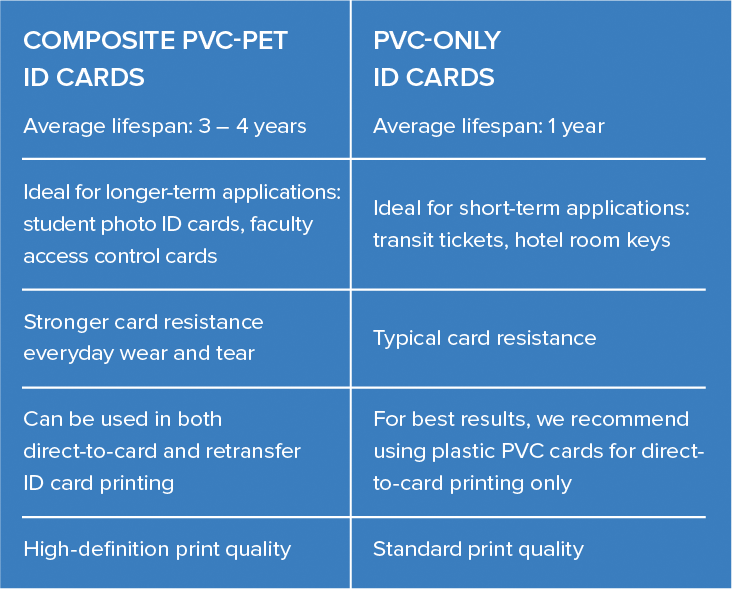

Unlike their plastic PVC card counterparts, composite ID cards are made of 60% PVC plastic with 40% PET material sandwiched inside.

Composite ID cards are just pennies more per card than PVC cards. They’re also much more likely to last through the school year than PVC cards, especially in the following situations:

- Students use the card repeatedly with a magnetic stripe reader

- Cards are frequently exposed to hot temperatures

- Student badges are made with a laminating or retransfer card printer that uses high heat

During the retransfer printing process, there's a significant amount of heat involved which ensures the successful fusion of the retransfer film onto the card’s surface. Because of this excessive heat, it's best to avoid using PVC-only ID cards as they tend to warp after being printed.

Product features (available in quantities of 100 or 500)

2. Anti-print transfer badge holders

ID holders are designed specifically to protect printed badges and extend the life of the card. However, when the badge is exposed to heat and pressure in the holder, part of the card image transfers to the plastic which is called dye migration. It typically occurs when ID badges are left in vehicles or are stored in the vinyl window of a wallet.

With an anti-print transfer badge holder, you’ll automatically eliminate the problem altogether, regardless whether you used a direct-to-card or retransfer ID card printer. These badge holders are made of an anti-print transfer material that won’t stick to or transfer print from ID cards onto the badge holder material.

Like all badge holders, anti-print transfer badge holders are available in both vertical and horizontal orientations for basic ID cards or proximity cards. They are also available in anti-print transfer earth-friendly badge holders, made from a PVC-free material.

Product examples (100 per pack)

- Anti-Print Transfer - Vertical - Heavy Duty Vinyl Proximity Badge Holder

- Anti-Print Transfer - Horizontal - Heavy Duty Vinyl Proximity Badge Holder

3. Custom lanyards

Custom lanyards increase card durability since users do not need to continuously take the badge out of their pocket during the day. They can be imprinted to showcase your organization’s name or motto, using tens of different colors.

There are three custom lanyard printing options for your convenience:

- Silk Screen: most common; best for simple text and logos; lowest cost per lanyard

- Dye Sublimation: high quality and long lasting; best for detailed logos or designs

- Woven: extremely durable with your custom design woven in; optimal for large projects

Product examples

4. Retransfer ID card printers

Badges made on retransfer card printers are 25% more durable. Why is this the case?

The technology prints onto the underside of a film and then heat rolls the image onto the card surface resulting in a more durable print. This is on top of the higher quality, crisper images, necessary when using barcode scanning.

Technology or proximity cards work best with reverse transfer ID card printers. The printhead does not come into contact with the cards, a large advantage since technology cards have uneven surfaces and embedded antennas or circuits.

Product examples

- Fargo HDP5600XE ID Card Printer - Single-Sided - 300DPI

- Fargo HDP5600XE ID Card Printer - Single-Sided - 600DPI

5. Lamination

Why laminate plastic ID cards?

Lamination extends the life of ID cards by protecting them from wear. Lamination is an additional clear or holographic layer available in various thicknesses that is applied after the card has been printed, and acts as a barrierto protect the images and text on your cards. The result is a much more durable card, optimal for high-usage cards like those swiped each day through a card reader.

Before ordering a laminating card printer, it's important to know that a number of laminating printers must be factory-ordered with lamination. Others can be upgraded to lamination in the field.

Product examples

- Evolis PrimacyID ID Card Printer - Single-Sided (add lamination)

- Datacard CD810 D ID Card Printer - Dual-Sided (can be configured with single-sided or dual-sided lamination)

The key to creating longer-lasting student ID badges for your school is to do a little studying of your own. By educating yourself with the information provided in this white paper, you can make a more informed decision – one that makes the most sense – for the unique needs of your students, staff and school.

As the new school season rolls around, partner with an industry leader you can trust. Call a knowledgeable ID Professional from ID Wholesaler today at (800) 321-4405. We know ID. It’s what we do.