Barcode Printing

There are three primary ways to access or store data on a card: a barcode, magnetic stripe, or smart card. If you do not have an encoding single-sided ID card printer or software with encoding capabilities, you can still use a barcode to access data on a card. The data is stored electronically in a computer, not within the barcode.

Requirements: All single-sided card printers are capable of adding a 1-D or 2-D barcode to a plastic card. You will simply need a barcode scanner connected to a computer that contains the barcode's data to read the barcode.

Magnetic Stripe Encoding

While a barcode's information is kept in a computer, information within a magnetic stripe is stored within the stripe of the card. When used for access control, for example, each card holds data that will unlock preprogrammed doors. Simply swipe the card and, if you are a validated user of that door, it will unlock.

There are two types of magnetic stripe cards:

High Coercivity (HiCo) magnetic stripe cards are harder to erase, and are used in applications where cards are frequently used or need to have a long life. HiCo stripes are resistant to damage from most magnets or magnetic fields and therefore are most often used for access control, timed attendance, and gift cards.

Low Coercivity (LoCo) magnetic stripe cards require a lower amount of energy to record and are easier to erase. LoCo stripes can be damaged by even a brief contact with a magnetic field. With this, LoCo cards are typically used for applications where the card is only used for a short time, such as hotel room keys.

Requirements: In order to use magnetic stripe cards, you will need an encoding single-sided ID card printer and mid-level or fully-featured ID software.

Smart Card and Proximity Card Encoding

Data is stored within the smart card components, similar to a magnetic stripe card. A smart card can hold up to 100 times more data than a magnetic stripe and offers added functionality. It can be reconfigured to add, erase, or edit hosted data. They can be categorized into two categories:

A contact smart card has an integrated chip. As the name implies, a contact smart card must come into direct contact with the reader in order to be read.

A contactless smart card has a chip and an antenna. In order to be read, it needs to come within a specified distance to the reader (varies by reader), but doesn't need to make direct contact.

Note: Proximity cards are similar to contactless smart cards, but there are important differences. Proximity cards come pre-programmed, so do not need to be encoded. Some single-sided card printers can read/verify data that has been written to a proximity card, but data on most* proximity cards cannot be added, erased, or edited.

Requirements: In order to use a contact or contactless smart card, you'll need a smart card encoding single-sided printer and fully-featured ID software. When ordering the printer, you'll need to specify whether you require contact or contactless encoding.

*Some cards, such as iClass cards, include non-editable, pre-programmed proximity data and a smart chip for encoding your own data.

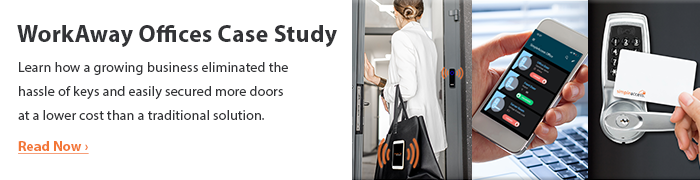

![SimpleAccess 500 Series Residential WiFi Deadbolt Remote Smart Lock]() SimpleAccess 500 Series Residential WiFi Deadbolt Remote Smart Lock Item#: OE-550DB-626Price $240.00 MSRP $289.00You Save: $49.00

SimpleAccess 500 Series Residential WiFi Deadbolt Remote Smart Lock Item#: OE-550DB-626Price $240.00 MSRP $289.00You Save: $49.00![SimpleAccess 4500 Series Light Commercial Duty WiFi, Card, and PIN Lever w/Lighted Keypad]() SimpleAccess 4500 Series Light Commercial Duty WiFi, Card, and PIN Lever w/Lighted Keypad Item#: kic-4510-ws-626Price $599.00 MSRP $649.00You Save: $50.00

SimpleAccess 4500 Series Light Commercial Duty WiFi, Card, and PIN Lever w/Lighted Keypad Item#: kic-4510-ws-626Price $599.00 MSRP $649.00You Save: $50.00![SimpleAccess 5500 Series Medium Commercial Duty WiFi, Card, and PIN Lever w/Lighted Keypad]() SimpleAccess 5500 Series Medium Commercial Duty WiFi, Card, and PIN Lever w/Lighted Keypad Item#: KIC-5510-WSPrice $699.00 MSRP $749.00You Save: $50.00

SimpleAccess 5500 Series Medium Commercial Duty WiFi, Card, and PIN Lever w/Lighted Keypad Item#: KIC-5510-WSPrice $699.00 MSRP $749.00You Save: $50.00