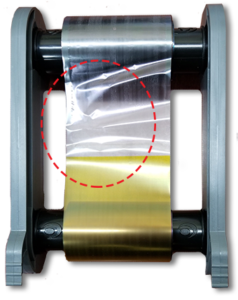

Card printer ribbons breaking is a common issue received by our tech support department. Luckily, it can be easily avoided  with routine maintenance. If your printer ribbon has torn, don’t toss the ribbon! Ribbons can usually be salvaged by taping them back together. After taping, however, you will want to take steps to prevent it from happening again.

with routine maintenance. If your printer ribbon has torn, don’t toss the ribbon! Ribbons can usually be salvaged by taping them back together. After taping, however, you will want to take steps to prevent it from happening again.

Step 1: Clean and calibrate your printer The easiest way to prevent ID card printer ribbons from breaking is to clean your printer regularly. Most printers should be cleaned after every ribbon change. Card printer cleaning kits are available for all printer models. After cleaning the printer and before installing a new ribbon calibrate the ribbon sensor, if it applies to your printer. Be sure to follow the manufacturer’s instructions for cleaning and calibrating your printer model.

Step 2: Check your card template Only retransfer printers (also known as "reverse transfer printers") can print to the very edge of the card. If you have a direct-to-card printer, avoid printing too close to the edge of the card as this will cause the ribbon to snap. Check your card design within your ID software program to make sure the margins are set to print within the card boundaries and, if necessary, increase the unprinted border.

Step 3: Restore to the default settings Changing settings in your printer driver can cause the ribbons to overheat. This typically happens when customers want to put more ink on the card in attempt to get darker, richer colors. Restore the driver settings to the default settings to prevent future breakage. If you try these tips and continue to have issues, give ID Wholesaler technical support a call at 800-321-4405, x4.