Choosing the printing method for ID badge creation is essential to producing your desired ID card. Both direct-to-card (also called “dye sublimation” printer) and reverse transfer (retransfer) ID card printers have ideal applications that must be considered before implementing or upgrading your ID card printer system.

Arguably, the most important determining factor of choosing between direct-to-card and retransfer printing is image quality and card type. The original form of ID card printing is direct-to-card printing.

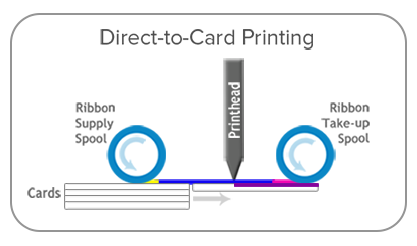

When printing on a plastic card, the printhead comes into direct contact with the card itself. A direct-to-card printer uses a dye-sublimation process to apply ink directly to the  surface of the card. These types of printers require ribbon (“ink”) and PVC cards to print and can include lamination modules as an upgrade. Direct-to-card printing is best for:

surface of the card. These types of printers require ribbon (“ink”) and PVC cards to print and can include lamination modules as an upgrade. Direct-to-card printing is best for:

- Basic credentials – Cards with white backgrounds and simple graphics

- Photo or visual IDs – it is not recommended to print on proximity/door access or technology cards if you use a direct-to-card printer

- Budget-friendly – Most economical solution for printing ID Cards

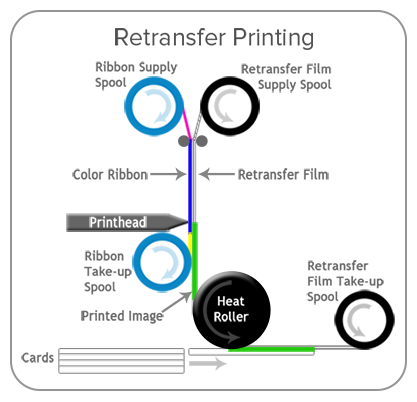

Reverse transfer printers use a newer form of technology to print ID cards. Instead of printing directly onto your card, a reverse transfer printer applies ink to a thin film which is thermally applied to your card. This means that your printhead never actually comes into in contact with the cards.

Reverse transfer printers require an additional consumable – retransfer film – along with ribbon (“ink”) and PET composite cards to print. Due to the thermal transfer of film to a card, it is recommended to use a PET composite card instead of PVC for printing. This will help avoid warping your cards and potentially damaging your printer. Reverse transfer printers also can include lamination modules as an upgrade.

Retransfer printing is best for:

- Superior image quality (up to 600 dpi printing) – Retransfer printers are able to print small text and detailed images.

- Over-the-edge printing – Retransfer printers are ideal for full-color backgrounds.

- Printing on proximity cards – Since the print head is never coming into contact with your card, retransfer printers are the ideal printing method to ensure the integrity of both your printer and card.

- Lifetime printhead warranty coverage – unavailable on any direct-to-card printer.

Essentially, determining what you want your card to look like and how you want your card to function is the best determinate on choosing between direct-to-card or reverse transfer printers. It’s also important to keep in mind that your card template may evolve in future.

By choosing a printer that is flexible to your needs (modular), your decision can be a more economical one in the long-run. It is important to know that once you've decided on one printing method or the other, your printing method is restricted to that specific printing type.

For help determining which type of ID card printing technology is the best fit for your organization's needs (now and in the future), you can rely on the expertise of our ID Professionals. Call today at (800) 321-4405; we're here to help!