Back in the 1800s during the Second Industrial Revolution, Englishman Lord Rayleigh researched the physical science of inkjet. Around the same time, piezoelectricity was more closely discerned by the Curie brothers (whose  sister, incidentally, was Marie Curie). Since then, the process of dye sublimation has evolved considerably, and a more advanced iteration of these combined technologies is still being used today. Where? In ID card printing, of course! The dye sublimation process for printing ID cards allows for the printing of photo lab-quality IDs on plastic cards as opposed to using an inkjet or laser printer on paper or Teslin paper cards.

sister, incidentally, was Marie Curie). Since then, the process of dye sublimation has evolved considerably, and a more advanced iteration of these combined technologies is still being used today. Where? In ID card printing, of course! The dye sublimation process for printing ID cards allows for the printing of photo lab-quality IDs on plastic cards as opposed to using an inkjet or laser printer on paper or Teslin paper cards.

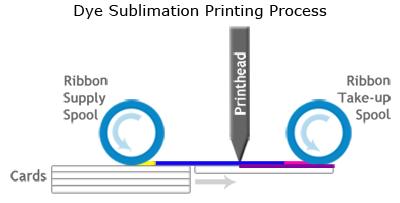

With dye sublimation printing (also referred to as "direct-to-card" printing), individual colors are not laid down as individual dots, as is done in inkjet printers. Instead, dye sublimation uses heat to imprint the image into the plastic card. With inkjet printing, individual dots can be distinguished at a relatively close distance, making digital images look irregular and less realistic. If you looked inside a dye sublimation printer, you would see a long roll of transparent film (we also refer to it as “ribbon”) that resembles panels of yellow, magenta, cyan, and black stuck together on spools. Embedded in this film are solid dyes corresponding to the four basic colors used in printing:

- yellow

- magenta

- cyan

- black

The printer’s printhead heats up as it passes over the film, causing the dyes to vaporize and press or force the ink into the plastic card. The vapors from the ink permeate the glossy surface of the plastic card before they return to solid form.

So the bottom line is this: the primary difference between dye sublimation printing and other types of printing has everything to do with heat. The vaporized colors infuse the surface of the card, creating a gentle gradation at the edges of each pixel, instead of the conspicuous border between dye and Teslin paper or the dye and paper produced by inkjet printers. And because the color infuses into the plastic card, it is also less vulnerable to fading and distortion over time.

With dye sublimation printing methods, it's the heat from the printhead that transfers a digitized image from the ribbon to the flat surface of a plastic card. This type of printing offers a variety of valuable advantages, including:

- Permanent images

- Extraordinarily brilliant colors from the bonding of the dye to the ID card

- Truly continuous tones that are equivalent to standard photographs

With ID card printers, there two types of printing: direct-to card printing and reverse transfer. Both of these printers use the dye sublimation method. The direct-to-card process depends on contact between the printhead, the ribbon, and the card’s surface. Therefore, uneven card surfaces cannot achieve high color density and uniformity when dye is transferred directly to a card.

For uneven surfaces, dye sublimation printing is achieved using the reverse transfer or "retransfer" method. The images are initially printed on transfer film as a reverse image of the final card design, which is then transferred into the card using heat and pressure. But that’s a topic for an entirely different blog!