We use cookies and similar technologies on our website to enable some essential functions for you. Learn more.

We use cookies and similar technologies on our website to enable some essential functions for you. Learn more.

FREE Standard Shipping Over $100

Tournament Time! Use MADNESS50 to take $50 off an order over $500. Save $150 on a purchase over $1,000 with MADNESS150.

Call us at (855) 215-4139 or

CLICK TO CALLChoosing the right ID card printer is critical for the success of your organization's ID printing program. This buying guide will help you make an informed decision with expert advice and top brand recommendations.

1. Assess Your ID Card Printing Requirements

Before purchasing an ID card printer, it's essential to define your specific needs:

Single-Sided vs. Dual-Sided Printing:

Decide if you need single-sided printing (prints on one side) or dual-sided printing (prints on both sides), depending on the amount of information you need on each card.

2. Compare Top ID Card Printer Brands

At ID Wholesaler, we are an authorized reseller of industry-leading brands known for their quality, reliability, and cutting-edge features. Popular brands include:

3. Key Features to Look For

When selecting an ID card printer, consider these crucial features:

4. Calculate the Total Cost of Ownership (TCO)

Don't just focus on the upfront price—factor in long-term costs such as ink ribbons, blank cards, and maintenance. Look for options with extended warranties and service coverage to minimize downtime and reduce overall expenses.

5. Get Expert Guidance

At ID Wholesaler, our experienced ID professionals are here to assist you. We provide award-winning support to help you choose the best ID card printer for your needs. Visit our website to browse our selection or contact us with any questions.

Shop ID Card Printers Today

Investing in the right ID card printer enhances the quality, security, and durability of your ID printing program. Explore our wide selection and get expert advice to make the best choice for your organization!

You’re off to a great start already! Once you know what you’re looking for, selecting the right badge maker (commonly referred to as an ID card printer) and establishing an ID card program is a simple process. We’re happy to help. If you have been asked to create an employee and visitor ID badge or membership ID card program for your facility – don’t sweat. You do not need to be tech savvy or knowledgeable about badge making to successfully implement and operate an efficient, cost-effective badge making program suited to your specific needs.

Badge Makers, known in the industry as ID Card Printers, are the foundation of all card printing programs. There are many brands and technologies available to choose from, and while making ID cards may be new to you, badge maker printers actually have a lot in common with standard inkjet printers. If you have used a computer printer, it should be relatively easy to understand and use an ID card printer. For an introduction to what an ID card printer is, how it works, and what to consider when shopping for the right printer for you, visit our resource center for our introduction to ID card printers video series.

Think of it as the difference between printing a two-sided or single-sided document from a standard computer printer. Single-sided badge makers print to one side of the card, while dual-sided badge makers can print to both sides of the card.

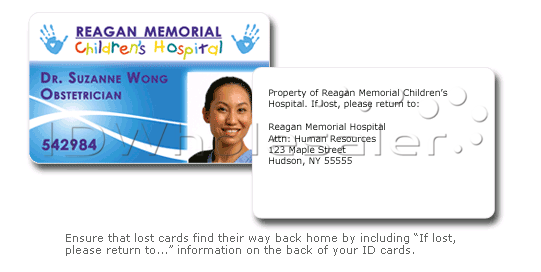

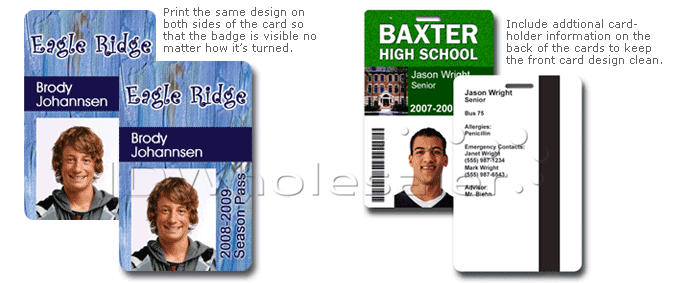

A single-sided badge maker is an economical choice if you will be printing a limited amount of information to your cards. On the other hand, a dual-sided badge maker lets you print information to both sides. Using a dual-sided badge maker allows you to keep the front of your cards looking clean and simple by displaying vital information only, while including additional information, contact information, or reference material on the back side of the card. Another option afforded by dual-sided printers that is particularly useful if your facility uses lanyards or badge reels to display ID cards is printing the same information to both sides of the card so that it is visible at all times, even if the card flips over or turns around.

If you remember the how ID cards were produced before modern badge maker technology was developed (spoiler alert: this was done by manually compiling individual components to a card face, then laminating the card to secure the components), you may be puzzled as to why lamination for printed cards is an option.

Well, here’s why. By laminating a printed ID card, you provide an added level of protection and security while extending the life of the card. Lamination is a transparent film applied directly to the card surface to provide the following benefits:

In addition to printing visual images and text to your cards, your badge maker or ID card printer is capable of printing barcodes for added security. Barcodes are an affordable way to store additional information on a card that can then be accessed by a computer or reading device. Barcoding is the most affordable encoding option for ID cards because it requires the least amount of equipment. However, barcodes are less secure than other encoding options, like magnetic stripe encoding or smart card encoding.

Requirements: All badge makers or ID card printers are capable of printing a 1-D or 2-D barcodes to plastic cards. To print barcodes to your cards, you will need to connect a barcode scanner to your computer and invest in ID card software that supports the barcode format that you will be using.

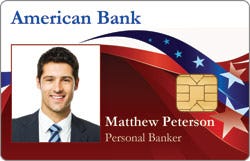

With barcoding, all the card information is stored to a computer. With magnetic stripe encoding, on the other hand, the information is stored right on the card and is contained within a black magnetic stripe (just like on a credit card). Magnetic stripe technology has many applications. Magnetic stripe encoded cards can be used as keycards for access control, or as time cards for logging employee hours. You are likely familiar with how “mag stripe” technology can be combined with point-of-sale devices to make transactions – this is possible because magnetic stripes can also be encoded with banking information. Magnetic stripes can also be used to store identification information similar or identical to the printed information on your cards as a precautionary measure to prevent counterfeiting.

There are two types of magnetic stripe cards:

Requirements: In order to use magnetic stripe cards, you will need an ID card printer that is capable of magnetic stripe encoding and mid-level or fully-featured ID software.

Like “mag stripe” encoding, smart card encoding allows you to store information right on the card (rather than on a computer). Smart cards provide additional functionality and have the capacity to hold up to 100 times the amount of data stored to a high coercivity magnetic stripe. Unlike barcoded and magnetic stripe encoded cards, smart cards are reconfigurable, meaning that you can add, edit, or erase data from them.

There are two types of smart card: contact and contactless. Contact smart cards have integrated chips that require direct contact with a smart card reader to access the stored data stored to them. Contactless smart cards have integrated chips too, but also have antennas so that the card holder only needs to come within a certain distance or proximity to the smart card reader to work.

Note: Proximity cards work like contactless smart cards, but they are pre-programmed and do not require encoding. Some badge makers can read and verify proximity card data, but in most cases* that data cannot be edited or altered as it can with a contactless smart card.

Requirements: To encode smart cards, you will need a smart card encoding ID card printer and fully-featured ID software. Be sure to specify whether you require contact or contactless encoding when ordering your printer.

*Some cards, such as iClass cards, include non-editable, pre-programmed proximity data and a smart chip for encoding your own data.

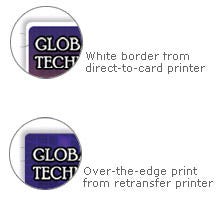

There are several key differences between direct-to-card and retransfer badge printers that you’ll want to consider when making your selection. The main thing you need to know about retransfer badge printers is that they can print to smart cards and proximity cards. Additionally, they allow you to print over the edge of the card, covering the whole surface, whereas direct-to-card badge makers will leave a white border.

Because direct-to-card printers print right onto the card, they require a perfectly even print surface. Attempting to print to an uneven surface (including the card edge) using a direct-to-card printer can cause expensive printhead damage. Enter retransfer technology. Retransfer badge printers eliminate pesky white borders by printing to a clear film that is then fused to the card, edge to edge. The printhead never comes into contact with the card directly, which means that you can print to uneven surfaces such as smart cards, proximity cards, pre-slotted or pre-punched cards, and key tag cards without risking printhead damage. An additional benefit to retransfer printers is their ability to produce imagery with rich, vibrant, saturated colors.

In conclusion: If you need to print on technology cards such as smart cards or prox cards, or if you will be printing to pre-punched ID cards, you will require a retransfer ID card printer.

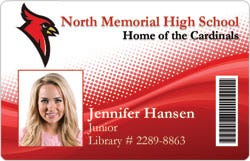

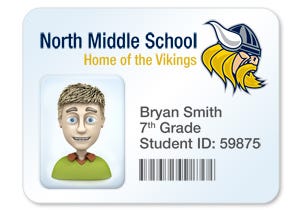

Before selecting an ID badge maker, you’ll need to consider the type and quantity of information or data that you want your cards to include. Answering this question will help determine the features you should look for in your badge maker or ID card printer. Remember: some card features will require special equipment or supplies.

To learn more about what information belongs an ID badge card, view or open the ID Badge Anatomy PDFs below:

The Anatomy of a Basic ID Badge

The Anatomy of a Basic ID Badge

The Anatomy of an Advanced ID Badge